Thermoelectrics

Thermoelectrics for Energy

Heat in Energy Use

Heat plays a major role in global energy consumption. Heat itself may the be final use of energy (e.g. residental heating). Heat is also a waste product in the transformation of energy, for example in electric power generation or transportation.

More than 60% of the energy produced in the U.S. is never utilized, most of it in the form of waste heat. Thermoelectric materials allow the direct conversion between thermal and electrical energy, and can therefore recover some of this lost energy. From the above chart, a major contributor to waste heat is in the transportation sector where only 20% of the fuel's energy ends up as useful energy.

Thermal energy (heat) is a common link between many forms of energy. This means that improving the net heat to electricity efficiency, or bypassing the thermal energy step altogether (as in fuel cells), will improve energy utilization.

Heat will be found in nearly all applications of energy, and that lost heat will represent a substantial portion of energy losses. Recovery of lost heat is a crucial step in reducing our energy requirements.

Improving thermal efficiency should be a major activity to reduce carbon dioxide emissions because its implementation will, in many instances, actually save money (figure below). Insulation improvements and efficient water heating will reduce carbon emissions and, over the long term, save more in energy costs than the cost of the improvements even without a carbon tax.

Waste Heat Recovery

Automobiles are an example of high energy usage with low efficiency. Roughly 75% of the energy produced during combustion is lost in the exhaust or engine coolant in the form of heat. By utilizing a portion of the lost thermal energy to charge the battery instead of using an alternator (adds drag on the engine) the overall fuel economy can be increased by about 10%.

Depending on the engine load the exhaust temperatures after the catalytic converter reach about 300-500 degrees Centigrade. Thermoelectric generators are ideal for such applications as they are small, with no moving parts, and relatively efficient at these temperatures.

Cogeneration of Heat and Electricity

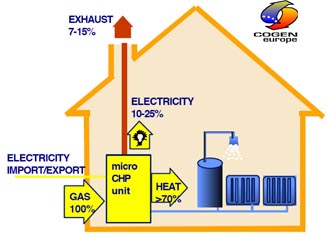

Because most electricity is produced by a heat engine, which is limited by Carnot efficiency, much of the energy is lost in the heat rejected. A typical steam power plant is only 40% efficient. The remaining heat is wasted, unless this rejected heat can be used for heating. The use of this heat then can add to the energy utility.

Conversely, any time a fuel is burned to make low temperature heat (such as in a home) the ability to produce useful work or electricty from that heat is wasted. A small cogeneration plant in the home would produce electricty whenever the heat is needed. The added fuel consumed to produce the electricity has essentially the same energy content as the electricity produced. Thus in terms of energy untilization the efficiency of electricity generation approaches 90% compared to the 40% in a typical power plant.

Thermoeletric systems are ideal for small (e.g. single family home) cogeneration because they could be small and silent. Even with their lower thermal to electric efficiency compared to dynamic heat engines, the electricity would be produced with high efficiency (electric power/extra fuel consumed) because the heat rejected will not be wasted.